Making Fuel Cells Work

Fuel cells offer considerable benefits, but developing them for commercial application has failed. To speed progress, a national program is needed to answer basic research questions.

For more than five decades, fuel cells have been heralded for their potential as a cost-efficient, environmentally friendly means to convert readily available chemical energy into electric energy. So far this potential has not been realized. In the United States, the foremost reason is that the federal government and the fuel cell industry have pursued a host of research programs that never systematically addressed underlying causes of fuel cell challenges, including reliability, longevity, and cost. Also in this process, the research community, which should have been a key player in this pursuit, has largely been on the sidelines. As a result, the fuel cell industry remains saddled with products that cannot compete with conventional sources of electric power. To set things right, the federal government should implement a national project to support basic research activity dedicated to obtaining detailed knowledge of fuel cell electrochemical operations aimed at solving fuel cell challenges and ultimately attaining commercially viable fuel cell products—at the earliest opportunity.

Fuel cells are singularly remarkable in their potential for efficiently converting the energy locked up in chemical bonds to electrical energy. This efficiency is achieved because fuel cells convert the chemical energy contained in a fuel into electrical energy in a single step, extracting more useful energy from the same amount of fuel than any other known device. An internal combustion engine, for example, requires several steps: converting chemical energy contained in gasoline to thermal energy via combustion, using the thermal energy to expand gases within the engine’s cylinders, and then converting the high-pressure gas to mechanical energy via the pistons and drive train. Because they rely on so many energy conversion steps, internal combustion engines are inherently inefficient and lose much energy to incomplete combustion and exhaust heat. As a result, most internal combustion engines deliver an average efficiency of less than 20%.

Fuel cells can deliver at least twice that efficiency. Moreover, if a fuel cell’s exhaust heat is exploited, total efficiency can be even higher. An internal combustion engine is most efficient under full operational loads (that is why car mileage is lower in city driving) and only at certain minimum engine sizes. A fuel cell, on the other hand, delivers high efficiency even while operating under partial design loads, and its high efficiency is scalable from very small units to very large units.

Fuel cells most commonly use hydrogen to generate electricity, but can use various other fuels, including gasoline, natural gas, ethanol, and methanol. Because of their efficiency, fuel cells using carbon-based fuels create less carbon dioxide and no other emissions, such as nitrogen oxide, that would harm the earth’s atmosphere. Hydrogen presents even a better future. Fuel cells using hydrogen generate no emissions (other than water) and so would have the least environmental impact. Moreover, hydrogen is inexhaustible on earth and can be produced from water through renewable forms of energy— including sun, wind, water, geothermal energy, and biomass—that are readily available in every country. Given their high efficiency, fuels cells, no matter the type, would also slow the depletion of the earth’s fossil fuel resources.

In the long run, fuel cell technology can cause a profound change in quality of life on a global scale. The technology has the potential to give individual citizens the ability to generate clean electricity at home instead of buying it from commercial power plants. Such plants commonly burn coal (and thus emit considerable amounts of carbon and other pollutants), and the electricity they produce is often delivered over great distances by an electrical grid that has high transmission losses and is susceptible to frequent—sometimes catastrophic—failures. Individuals also could drive cars that operate on hydrogen instead of gasoline, thereby dramatically reducing their carbon footprint. Fuel cell technology can spur the development of new classes of energy demand and supply systems, transportation systems, and industrial and manufacturing systems around the globe, while generating trillions of dollars in new revenue. In addition, oil importing nations can cut down on the use of oil, thereby gaining greater independence from oil-producing nations, enhancing their energy security, economic security, environmental security, and the national security.

When fossil fuel is depleted or becomes very costly to obtain, the world will be left with only three energy-conversion options: nuclear fission, nuclear fusion, and renewable energy. The first two options face serious obstacles. Nuclear fission uses uranium, which like oil is a natural resource with high access cost. It also generates long-lived, hazardous radioactive wastes. Nuclear fusion will not be ready for another 40 years. Fusion-powered electricity generation was initially believed to be as achievable as fission power. However, the extreme requirements for continuous reactions and plasma containment have led to projections of feasibility being extended out by several decades. In 2010, more than 60 years after the first attempts, commercial power production is still believed to be unlikely before 2050.

Renewable energy, at least in today’s most common forms, also faces obstacles. Common renewable energy technologies depend on sunshine and wind or biofuels, which are either intermittent, unreliable, or environmentally unfriendly. The best option with renewable energy will be, without doubt, the fuel cell.

Effort, but little progress

The federal government and its partners in industry have long recognized the promise of fuel cells and have worked together to develop fuel cell technology, infrastructure, and manufacturing capabilities. The government alone has devoted billions of dollars in research and development to fuel cell technology in the past 50 years, and corporations have invested similar amounts.

The Department of Energy (DOE) has been in the lead in promoting fuel cell development over the past two decades, spending $2.4 billion on applications research and product development. Most of the effort has focused on developing four types of fuel cells intended for generating power for electric utilities, and on a fifth type, which has received attention more recently, for generating power for vehicles.

But public and private efforts have not delivered on their promise. They have yielded almost no products that can compete with conventional power sources, at least without subsidies and tax credits. Major impediments to fuel cell commercialization include insufficient longevity, reliability, and, in many cases, unacceptably high cost.

Here is a brief summary of these efforts and the results that were achieved:

Alkaline fuel cells. In the 1960s, the National Aeronautics and Space Administration was searching for a source of long-endurance power on manned space flight missions, and decided that alkaline fuel cells (AFCs) would be promising. Rather than try to develop AFCs on its own, the agency asked the United Technologies Corporation to develop them. The company succeeded, and its AFCs were used for the Apollo missions to the moon, the Skylab space station, the Apollo-Soyuz rendezvous and docking mission, and subsequently the Space Shuttle Program. After achieving success in space missions, the company attempted to adapt its technology to terrestrial applications. But it ran into a major problem: AFC performance is easily degraded by very small amounts of carbon dioxide. AFCs used in space missions could be physically isolated from any carbon dioxide generated by the astronauts, and so this was not an issue for these applications. But removing all carbon dioxide from ambient air on earth would be extremely expensive, and so AFCs built for terrestrial applications had short lifetimes and consequent high cost. After considerable effort to solve the problem, the company eventually abandoned the idea. Today, no U.S. companies are engaged in R&D on alkaline fuel cells.

Phosphoric acid fuel cells. DOE’s Office of Fossil Energy began funding development projects for phosphoric acid fuel cells (PAFCs) in the mid-1970s, in collaboration with several industry-funded groups, including the Gas Research Institute, the Electric Power Research Institute, and an electric utility consortium. The United Technologies Corporation was the primary contractor. The government and industry undertook this joint effort out of concerns about the cost of controlling emissions from coal-based plants and the rise in cost, complexity, and procedural delays for nuclear installations. After a series of efforts to scale up its PAFC systems to reduce cost, United Technologies began, with DOE’s blessing, to promote its technology for commercial sale. But the high price tag discouraged U.S. electric utilities from making any purchases of the company’s initial 11 megawatt power plant. A typical PAFC power plant was priced at $4,360 per kilowatt hour (kW), and installation costs added an additional $2,000/kW. This was more than six times the nominal $1,000/kW cost for conventional power plants.

Despite the lack of interest from utility companies, the company moved ahead with commercialization of a 200 kW system in the early 1990s. Just as DOE’s support for R&D ended, the federal government began to assist United Technologies by offering a series of subsidy programs that promoted commercialization of the company’s PAFC power plants. These programs remained in place for two decades, but they did not succeed in establishing a going market for the technology. In December 2012, the company sold its power unit (UTC Power) to CleanEdge Power, a small fuel cell company. This effectively ended some 50 years support by United Technologies to promote fuel cell technology—the last major U.S. corporation in the fuel cell industry.

By the time DOE terminated its support, it had spent $300 million on various PAFC power plant development activities. Although the government’s funding assisted the private sector to scale up PAFC technology and demonstrate pilot power plants in the field, the efforts did not solve fuel cell price-performance problems and failed to achieve a level competitive field with other sources of electric power.

Molten carbonate fuel cells. DOE’s support, through its Office of Fossil Energy, for molten carbonate fuel cells (MCFCs) yielded equally depressing results. Funding for initial technology development began in 1975 and continued for 30 years, ultimately reaching $481 million by 2005.

With federal funding, companies were able to scale up their systems and conduct field demonstrations of pilot power plants. But MCFC power plants remained extremely expensive and were sold only with major subsidies and other incentives. Today, only one U.S. manufacturer—Fuel Cell Energy—offers power plants of this type, but the company’s position in the business is increasingly tenuous. Its records indicate that 94% of sales in the United States were concentrated in Connecticut and California, states where subsidies were the most generous. Few other states showed interest. Also, the company depends increasingly on POSCO Energy of South Korea. Sales to POSCO increased from 6.4% of total sales in 2009 to 44% in 2011. Moreover, Fuel Cell Energy has licensed POSCO Energy to use its technology to build power plants in South Korea, eroding the company’s prospects as a manufacturer of MCFCs.

Solid oxide fuel cells. In 1977, DOE’s Office of Fuel Energy signed a five-year, $202 million agreement with Westinghouse— later Siemens Westinghouse Power Corporation— to improve its unique tubular design for solid oxide fuel cells (SOFCs). The design involved forming small hollow tubes with cell components layered on the inside wall of the tubes. The technology proved exceptionally difficult to master, however, and by 2003 lifetimes still were too short and costs were too high to be commercially viable. In 2010, the parent company, Siemens of Germany, put the SOFC business up for sale, after investing more than $1.5 billion and running the company for 10 years.

Having watched this effort fail, DOE launched a 10-year R&D program in 2000 that focused on new planar designs, where components are assembled in flat stacks one on top of the other as well as more innovative tubular designs for SOFCs. Called the Solid State Energy Conversion Alliance (SECA) program, it was intended to develop an SOFC system that would cost as little as $400/kW by 2010, which was a remarkable goal, considering that the Siemens-Westinghouse designs cost in the range of $17,000 to $26,000/kW.

A critical component of DOE’s plan was to undertake basic research—a step that represented a departure from its previous support for fuel cells. The SECA program instituted a core technology team that would conduct basic research to support the industry teams that would design and fabricate the fuel cells and systems. The core technology team was made up of research entities, including universities, national laboratories, and small businesses, and was to engage in precompetitive research that addressed issues common to all industry teams. The goal was to identify and isolate the underlying causes of fuel cell performance problems in order to drive down costs.

Unfortunately, the SECA program suffered from constant tinkering with its goals. Over a period of five years, SECA was transformed into a program to develop a class of SOFC power plants that would be fueled by coal gas and would produce electricity in the megawatt range; then it was incorporated into a FutureGen initiative to build a fossilfuel power plant that would produce electricity and hydrogen gas without harmful emissions; and transformed yet again into a FutureGen initiative that would use so-called Oxy-Fuel technology to capture carbon dioxide emissions. By the end of the decade, SECA’s fundamental cost reduction goals, which were critical to successful commercialization of SOFCs, had been entirely lost.

One of the more disheartening consequences of these changes was that SECA’s core technology research program lost focus. Although the program received more than $467 million between 2000 and 2010, relatively little went to its basic R&D mission. Consequently, the core technology team did not examine the fundamental principles and mechanisms regarding the physics of fuel cell electrochemistry as it had intended. Rather, it gave priority to “symptomatic relief ” of fuel cell performance problems. Projects became so small in scale—many were under $1 million—that they could not advance fuel cell technology and enable a paradigm shift in cost and longevity. In the end, with lack of funding and commitment by DOE, the SECA program effectively ended in 2012.

Today, the SOFC industry in the United States lacks focus and a clear path for growth. There are about a half dozen SOFC developers in the country; none has publicly disclosed its profitability. Overall, the history of SOFCs is a familiar one: in the absence of a SECA-like project that would systematically support basic research, it is very unlikely that the SOFC industry will achieve breakthroughs in power densities and efficiencies that would yield competitive cost-performance.

Proton exchange membrane fuel cells. Throughout the 1990s, DOE, through its Office of Energy Efficiency and Renewable Energy, supported a small amount of R&D on proton exchange membrane fuel cells (PEMFCs). That changed in 2002 when the Secretary of Energy announced implementation of the FreedomCAR Initiative to develop fuel cell vehicles that would run on hydrogen fuel. In the following year, President George Bush, in his State of the Union Address, announced the Hydrogen Fuel Initiative, which aimed at developing technologies and infrastructure to produce, store, and distribute hydrogen for fuel cell vehicles. The two initiatives were combined into the Freedom-Car and Fuel Partnership.

The partnership ran into implementation problems almost from the start. It inherited the existing organization, the Partnership for a New Generation of Vehicles, that had been formed in 1993 by the federal government and a group called USCAR, an association of Big Three U.S. automakers. This arrangement clearly did not serve the purpose of advancing fuel cell technology R&D. The automakers had commitments to conventional automotive technologies, which discouraged them from focusing on long-term, high-risk fuel cell R&D, particularly if near-term combustion engine technologies were competing for the same funding. So not surprisingly, fuel cell R&D always received a smaller share of funds than hydrogen or conventional vehicle technologies within the total budget.

Reflecting the disadvantaged position of fuel cells in the FreedomCar and Fuel Partnership, the budget devoted to PEMFCs fluctuated constantly. It increased from about $20 million under the original partnership arrangement to as much as $64 million in 2004, declined to $34 million by 2006, only to increase again and decline again in the next few years. Throughout the decade, these fluctuations likely made long-term equitable planning for fuel cell R&D difficult and might have resulted in multiple, insignificant, unrelated, short-term projects. In contrast, the budget for conventional vehicle technologies always received much more funding each year, with no ups and downs. Total funding for the FreedomCAR and Fuel Partnership amounted to $1.6 billion (2002-2012), which was spread among R&D for fuel cells, hydrogen storage technology, advanced combustion and emission control, vehicle systems analysis, and other initiatives. Of the total, fuel cell R&D received $500 million, about 30%.

Was the fuel cell R&D program under the partnership effective? The National Research Council (NRC) reviewed the program and offered mixed findings. In its 2010 report, the review committee spoke well of some of the achievements in the program. It cited an increase in demonstrated lifetimes of fuel cell stacks for on-road vehicles. Indeed, the partnership likely facilitated the entry of some PEMFC products into niche markets, including forklifts and backup power applications. Still, DOE’s 2012 annual progress report stipulated that these products were cost competitive only if subsidies of $3,000/kW were provided and only if they were used for low-power, short duration applications.

The NRC, however, was clearly disappointed that no single fuel cell technology achieved a performance-cost point that would make it competitive with conventional vehicle technologies. In fact, few PEMFCs developed under the program were deployed in the automakers’ own fuel cell vehicles. At the same time, U.S. automakers do not seem to have any near-term plans for new development or commercial launch of fuel cell vehicles.

Why so hard?

What makes fuel cell technology so difficult to master? The answer is simple. Fuel cell operations are complex and the necessary research has not been systematically done to master them. Ironically, this state of affairs is partly due to the fact that it is easy to make a single working fuel cell in the lab, but building fuel cell stacks that generate useful power reliably, efficiently, and cheaply is another matter entirely. History is full of stories in which fuel cell companies developed moderately functional fuel cells, scaled them up for commercial applications (often with government assistance), and rushed the product to market. They subsequently found that their fuel cells did not work well. No matter how many times they encountered problems of cost or efficiency or reliability, however, they always believed things could be fixed with a little more time and a little more money. They were looking for tactical fixes when strategic solutions were needed.

The challenge of making reliable, efficient fuel cells is rooted in the complexities of how they operate, which involves multiple chemical and physical interactions at the atomic level. Perhaps no advanced technology on the market today—including airplanes, computers, or even nuclear reactors—requires the scale, magnitude, and range of scientific, physical, and engineering knowledge that fuel cell technology requires.

Science is making progress, however. Recently, some scientists have successfully applied advanced research tools to understand fuel cell operations at the atomic level and are developing theories to explain details of fuel cell processes. Several examples suggest that this type of work, if integrated into a single collaborative effort, could achieve groundbreaking discoveries that would ultimately lead to viable commercial products:

• Researchers at Tohoku University recently demonstrated how computational chemistry can advance fuel cell development. They linked computationally obtained images with the images obtained from transmission electron microscopy and proved for the first time how computational chemistry can duplicate real-life degradation [of the catalysts? of the electricity-producing materials?] in fuel cells. They have used this discovery to develop a theory of such phenomena, which will help to lay the groundwork to fix the problem.

• Researchers at Yamanashi University and Waseda University, working with others at Shimadzu Corporation, Fuji Electric, and Hitachi, have succeeded in imaging the oxygen distribution within a fuel cell stack for the first time. They used a chemical reagent that absorbs light and emits light of a specific wavelength when oxygen is present and captured an image of oxygen distribution with a charge-coupled device camera. The visualization of the inner working of a fuel cell stack could reveal mechanisms of fuel cell deterioration. They are currently working on the simultaneous visualization of humidity, steam, water, temperature, and carbon dioxide within a fuel cell stack.

• Researchers at Oak Ridge National Laboratory have used a novel microscopy method called electrochemical strain microscopy to successfully examine the dynamics of oxygen reduction/evolution reactions in fuel cell materials, which may reveal ways to redesign or cut the costs of the energy devices. According to the researchers, if they can find a way to understand the operation of the fuel cell on the basic elementary level and determine what will make it work in the most optimum fashion, it would create an entirely new window of opportunity for the development of better materials and devices.

• Researchers at Los Alamos National Laboratory have developed nonprecious-metal catalysts using use carbon, iron, and cobalt to avoid the use of expensive platinum catalysts in hydrogen fuel cells. The team says its next step will be to better understand the mechanism underlying the carbon-iron-cobalt catalyst. Such an understanding could lead to improvements in nonprecious-metal catalysts, further increasing their efficiency and lifespan.

Too valuable to abandon

In considering the disappointing experience with fuel cells, the federal government faces a choice. One option would be to abandon fuel cell development altogether. Another option would be to provide assistance to sustain the temporary survival of the industry. Neither of these options is attractive—or necessary.

Rather, the government can implement what we see as a National Fuel Cell Development Project (NFCDP) that would focus on basic research. Over the past decades, the U.S. federal government, with other governments worldwide, have worked vigorously to help their fuel cell industries build technical capabilities that yielded little economic return. These efforts rested on an assumption that fuel cell technology could be developed into commercially viable products, given enough investment and time to make incremental improvements through applied research and product development. But despite the best of intentions, the fuel cell industry remains in a commercial cul-de-sac and continues to ask for government assistance for survival, including demonstration projects, tax incentives, and subsidies for lowering purchase costs and building a hydrogen infrastructure. Governments are reluctant to stop fuel cell subsidies because they have already invested so much in the industry. And yet, they cannot continue the same policy and subsidy program as before. It is expensive, unproductive, and never ending.

The only viable path ahead is the NFCDP. The federal government should support a basic research strategy and do so as a matter of urgent national priority. Indeed, the NFCDP would focus solely on adding basic research as a key component to the traditional mix of applied research and product development activities that DOE has been implementing for years.

Once fuel cell technology is fully understood and the mechanisms that effect fuel cell performance are known, the fuel cell industry would be able to produce commercially feasible fuel cell prototypes, test them, and acquire solution to every remaining problem within the NFCDP framework. Large-scale simulation, best exemplified by the automotive and aerospace industries, if also implemented, would expedite the commercialization building up from materials and fundamental understanding all the way to manufacturing and distribution of fuel cell products to the marketplace. Thus, the industry could launch commercial products virtually immediately when the project ends, because it already would have a mature technology, well-developed manufacturing capabilities, and marketing infrastructure in place.

The bottom line is that if fuel cell applications are to be successful, basic research must first be successful. Although basic research, applied research, and product development would co-exist in the NFCDP, it should set basic research as its central and primary mission from the start. The project should ensure that basic research always be given the highest priority and that it be kept unencumbered from applied research and product development. Without this protection, basic research will not be able to compete with other research activities; research would likely be directed to abandon its knowledge-seeking mission and shift toward forprofit research that is normally carried out through applied research and product development activities.

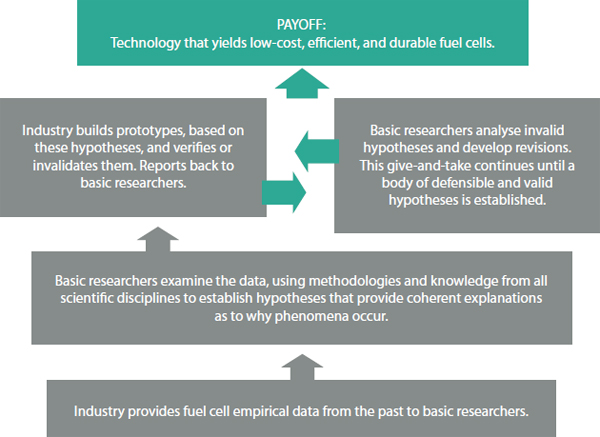

At the same time, however, the NFCDP will not be successful unless it links basic scientific research and hypotheses generation to technology development and the empirical data acquired by industry. (This flow is illustrated in Figure 1.) Throughout the life of the project, therefore, the fuel cell industry should have complete access to the NFCDP’s research findings and discoveries and be encouraged to apply these to product development and manufacturing activities. Industry should give the NFCDP continuous feedback on whether fuel cell technology was becoming more durable, efficient, and cost effective. It is essential that industry be fully integrated with the project from start to finish and that companies receive strong incentives to share their information on fuel cell technology and assurance that proprietary data will be protected. The repeated cycle of hypothesis, verification, and data exchange between basic research and applied research and product development will yield improvements in knowledge of fuel cell performance with every step.

What it will take?

The NFCDP’s central and vital mission would necessitate assembling a highly talented cadre of scientists and engineers from all related disciplines in the research, academic, and industry communities. Together they would comprise a critical mass of expertise, knowledge, wisdom, and practical know-how that has never been gathered before for this purpose. The team should be practically and virtually colocated to ensure that team members will be able to integrate their knowledge and collaborate on discoveries in all phases of the project. Most importantly, the team must be led by a strong, can-do manager who has direct access to the nation’s most senior leadership.

The project should be backed at the highest level of priority associated with national energy security policy. Project leaders should be placed directly under the president and be provided with ample resources to explore all possible technology options and momentous freedom. Project leaders also should be granted broad authority to take whatever actions needed, including hiring and firing top leaders and enlisting the nation’s top-quality research cadre.

The NFCDP should have unrestricted access to the national laboratories. They have served as the federal government’s core institutions dedicated to basic R&D and should be deployed as the core of the project’s R&D infrastructure. Importantly, the project must be supported with ample financial resources and extensive research facilities. A research period as long as five years would be desirable to encourage the stability of the research team and continuity of the research environment, while still ensuring that the research team is focused on the tasks at hand. Major technical hurdles can be overcome only through intense, massive investment of resources in a concentrated period.

As a first step toward this goal, a Blue Ribbon committee of top leaders from national research laboratories, industry, and funding agencies should be assembled, under the leadership of the National Academy of Sciences, and charged with preparing a detailed blueprint for implementing the NFCDP.

Among other actions, the committee should identify specific areas of research to be explored. Probable areas of research likely might include the discovery and detailed characterization of fuel cell electrochemical processes and operations; development of a theoretical understanding and empirical validation of underlying causes that drive performance shortfalls, such as cell degradation and insufficient longevity, reliability, and robustness; and exploration of transformational technologies that would enable creation of revolutionary fuel cell types, catalysts, and supporting components using new, less expensive materials. The committee also should identify a range of disciplines that will be needed to support research activities. Research areas likely will include computational chemistry, molecular chemistry, surface chemistry, quantum chemistry, quantum electrodynamics, electromagnetism, mechanical engineering, metallurgical engineering, materials science, mathematics, molecular dynamics, quantum dynamics, thermodynamics, nanotechnology, quantum mechanics, statistical mechanics, atomic and molecular physics, experimental physics, computational physics, nuclear and particle physics, quantum physics, solid-state physics, theoretical physics, and many more.

Of course, there is no guarantee that an effort such as the NFCDP would lead to delivering successful products; it is a necessary, but not sufficient step. Without it, however, there is no reason to believe that fuel cells will make enough progress to become commercially viable. History has proven that to be the case many times over.

Regardless of who would implement the National Fuel Cell Development Project, whether it is the United States or some other country, the world would benefit equally, in terms of a higher standard of living and a cleaner environment. The time to begin is now. Society has in its grasp the scientific and technical know-how to uncover the secrets of the fuel cell—to discover how it works, why it works, and how it can be made to work better.